Summary and Features

Lighting can be installed and replaced safely and easily on high ceilings such as factories and warehouses.

High Safety

Guide-and-pin system ensures secure mounting on forklift tines.

Lightweight Design

Aluminum construction weighs in at just 60kg.

Maintenance-Free

Aluminum construction eliminates worries about rust.

Affordable

Low cost, even despite the use of more expensive aluminum construction.

Compact storage

Folds into 1/3 its extended size for easy storage when not in use.

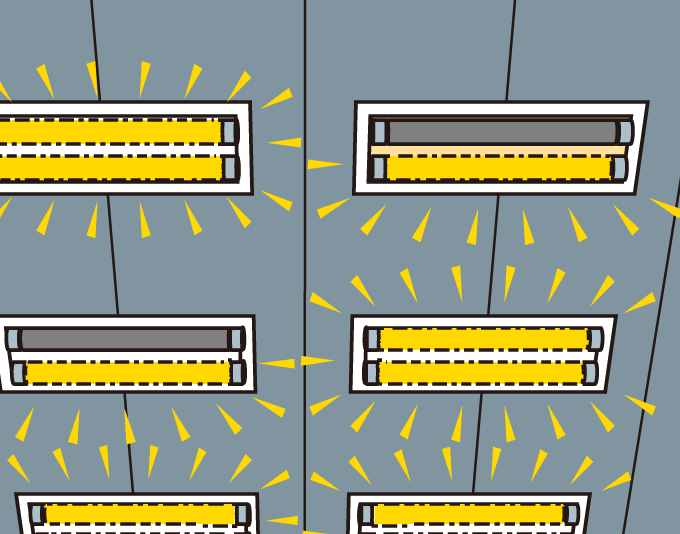

Let’s solve the Problem of Changing Lightbulbs

Fluorescent Tube Lifespans

Fluorescent tubes often don’t last as long as other kinds of lighting, and they tend to be irregular in the timing with which they burn out.

Unexpected Accidents

Poor lighting caused by burned out fluorescent tubes can lead to decreased efficiency and even accidents.

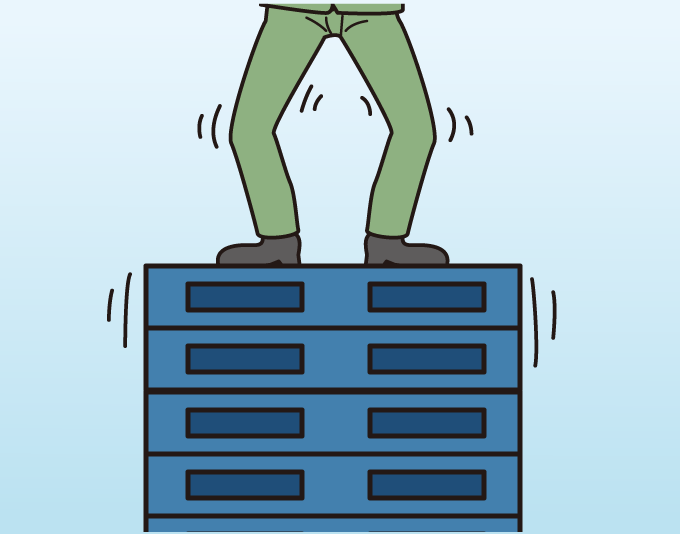

Dangerous Working in High Places

Many places hire electricians to change burned-out lights in high places, or do it themselves by having workers climb onto stacked up pallets. Naturally, this can be dangerous work, and accidents can happen easily, with just one slip or fall. Clearly there is a need to be able to exchange burned-out tubes safely and quickly in order to return the workspace to fully illuminated efficiency.

SAFETY CART solves these lighting replacement challenges.

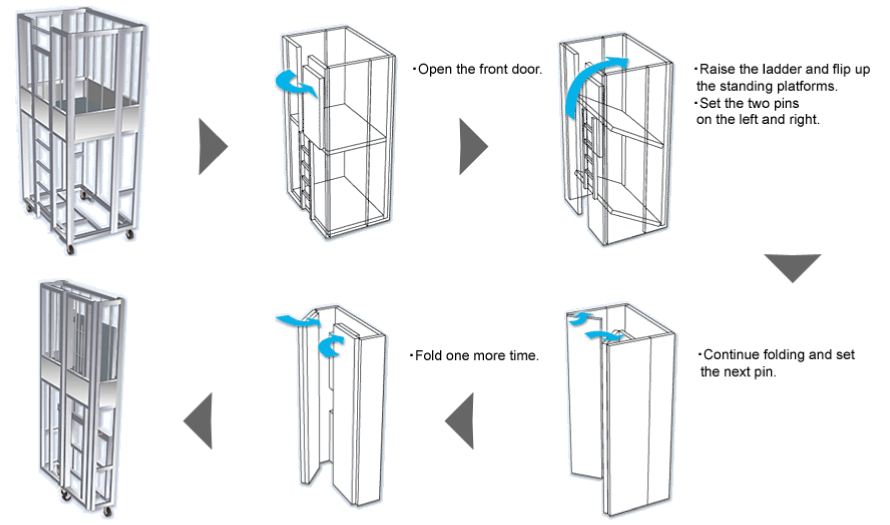

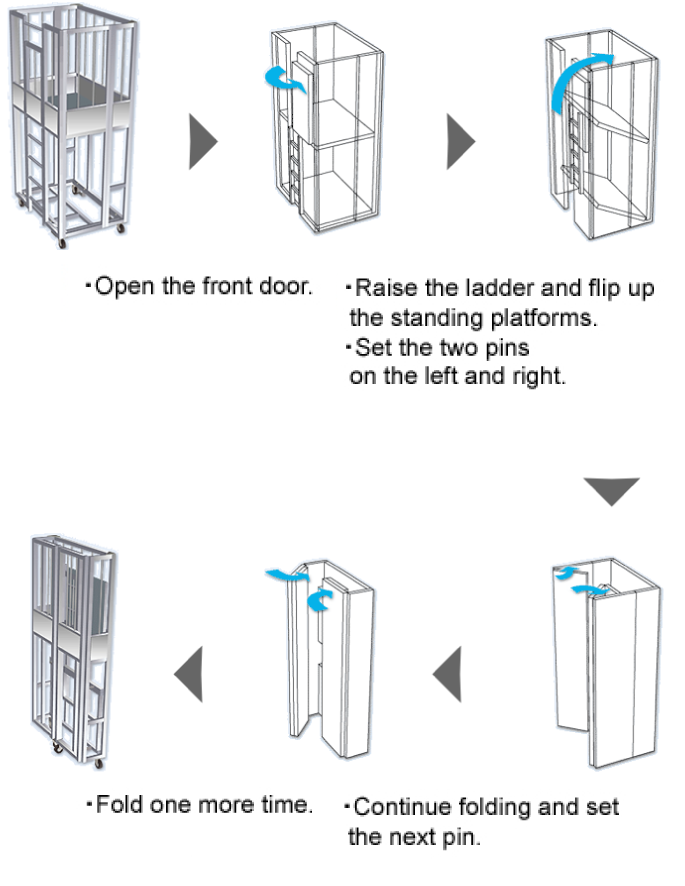

Folding Steps

The Industrial Safety and Health Law

(Limitations on Riding)

According to section 13 of article 151, when conducting work using wheeled cargo-carrying equipment (exempting vehicles for use on uneven ground and cargo-carrying autotrucks), workers may not board any area other than the operator seat. However, this does not necessarily apply when adequate measures have been implemented to prevent worker falling danger.

(Limitations on Usage for Other than Primary Purposes)

According to section 14 of article 151, when using wheeled cargo-carrying equipment to lift cargo, these must not be used for purposes other than the main ones for which the equipment was designed, and this includes carrying workers as riders. However, this does not necessarily apply at times when workers will not be placed in harm’s way.

Interpretation

However, the passage “when adequate measures have been implemented to prevent worker falling danger” refers to the preparation of fences or other enclosures that prevent workers falling from heights from slide carriers or from moving wheeled cargo-carrying equipment.

Interpretation

(1) This article specifies measures to protect against not only falling, but also pinching, being drawn in, and other dangers.

(2) However, the phrase “at times when workers will not be placed in harm’s way” refers to those situations in which there is no danger of the forklift or other equipment toppling, when rails or borders of sufficient height have been prepared around the pallet, when the pallet has been attached securely to the forks, and/or when worker safety nets have been installed.

It is forbidden for a worker to ascend riding on a pallet loaded on a forklift, and if an accident does occurs as a result of such an action, the matter shall be addressed to the Labor Standards Bureau, the jurisdictional police and other relevant authorities, and the management, including both individuals and the company, may be penalized.

Specifications and Drawings

| Weight Capacity | 100kg |

|---|---|

| Dimensions (W×L×H) | 800×1,100×2,400mm |

| Folded Dimensions | 350×1,100×2,400mm |

| Weight | About 60kg |

| Functions | Movement: Casters (4 places), free, stoppers (2 places) Fork guides: Pin type |