Summary and Features

Circulation system.

Dedicated pallet circulation type vertical conveyor.

Reduces running costs

Instead of the normal twelve annual inspections to which elevators are normally subject, the Omni Lifter PL Type needs only four voluntary self-inspections a year, cutting running costs dramatically.

High operating efficiency

A special pallet is always waiting at the loading gate, allowing constantly smooth loading and unloading. Special pallet movement is also completely automatic to ensure better safety.

No construction permit required

Unlike elevators, installation of the OMNI LIFTER PL Type does not require application for a construction permit.

Pallets and carts can be transported together.

Also allows combined use of forklifts and handlifts.

Absolutely no need to adapt carts.

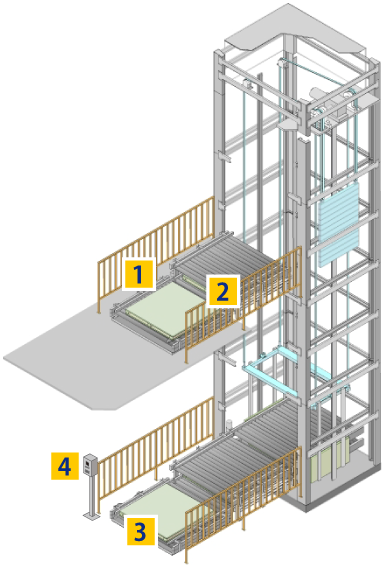

Main Devices

1. Checking device for

a figure of products

This device checks a protrusion of the products and prevents an accident.

2. Two steps auto feeding device

It is quite safe because products on a pallet move automatically to a lifter conveyor.

3. Loading plate

with lifting function

The lifter repeats to go up and down.

Products on a pallet will be carried in and vacant pallet will be carried out.

4. Standard control box

(Touch panel)

Cases

Specifications and Drawings

| Model | 3PE-H-6-10-PL |

|---|---|

| Max. Cargo Weight | 1,000kg |

| Cart Dimensions | 800W×600L×1,800H (2 each) |

| Pallet Dimensions | 2,000W×1,200L×60H (Special Pallet) |

| Loading Method | Manual push |

| Loading Orientation | Load and unload from front |

| Conveyance Capabilities | 1F-2F:70 Pt/hour; 1F-3F:50 Pt/hour |

| Conveyance Speed | 50m/min |

| Lifting Power | 11kW |

| Table Dimensions | 2,420W×2,000L |

| Lateral Speed | 24m/min, inverter controlled |

| Lateral Drive Power | 0.75kW、4P、GM |

| Loading Mechanisms | 2 per floor, 6 total |

(Unit: mm)

【Additional Work Requirements】

| 1. | Run primary power supply to the 3F control panel (3φ、200V、50Hz、30.7kW) |

|---|---|

| 2. | Each floor – Install smoke shutters (3 sides) |

| 3. | Conveyance passage-Fire protection sectioning off |

| 4. | Wire emergency controls for fire outbreak signal (24V DC) |

| 5. | Upper conveyance passage-Install construction-use lifting hook (3each, 2-ton capacity) |

| 6. | Upper conveyance passage – Install lighting (40W) |

| 7. | Upper conveyance passage – Install pressurized exhaust fan with 40°C thermocouple switch and anti-fire/anti-smoke damper |

| 8. | 3F – Install 100V electrical outlets |

| 9. | 3F – Install inspection door |

| 10. | 1F – Construction of base for main unit, pit construction (concrete), and opening of floors on each level |

| 11. | Run temporary power lines for use during construction |

| 12. | Install anti-harmonic measures |

| 13. | Other-General construction related to structure, electrical, equipment, and anti-disaster measures |

Special Pallet Reference Dimensions

| Width | 2,500W・2,100W・1,800W |

|---|---|

| Depth | 1,600L・1,500L・1,400L |

Special Pallet Dimensions, 9 patterns

| Dimensions | 2,500W× |

2,500W× |

2,500W× |

|---|---|---|---|

| 2,100W× |

2,100W× |

2,100W× |

|

| 1,800W× |

1,800W× |

1,800W× |

(Unit: mm)