Summary and Features

A slide slope that is movable and can be used as a track leveler to eliminate steps.

Three functions in one unit

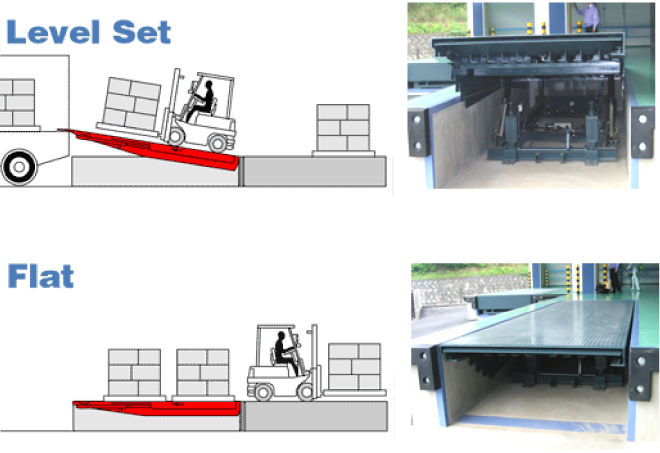

When a truck arrives, use the levelerbetween the dock and truck (max. angle 9.5°) to create a stable bridge between the two. Or, if you want to eliminate the height-difference between the loading platform and the ground below, simply lower the leveler all the way down to create a gentle slope. When not in use, simply leave the leveler at 0° to serve as usable space.

This three-in-one Climbing Leveler is recommended for all kinds of loading docks and platforms.

Fast Up & Down Movement

Moves up to connect to trucks in about 30 seconds, or all the way to the ground in about 45 seconds, both fast enough to improve work efficiency.

Rated up to 5 Tons

The Climbing Leveler uses SS41 steel construction for a rated load capacity up to 5 tons and to ensure safe, stable operation.

Create a Stable Slope

The CLIMBING LEVELER creates a sliding slope about 500mm in the up position or 1,000mm in the down position, allowing forklifts to ride over it without instablity.

Let’s solve the Step Leveling Problem!

Most loading docks are designed with truck height in mind, and also have slope mechanisms that allow forklifts to come and go.

The problem, though, is that installing such slopes means that many trucks can’t find the right berth, and they end up lined up outside on the roadside, in many cases inconveniencing the neighborhood.

Many loading docks have dock levelers that eliminate truck-dock height differences, but some—like container trucks—are so large that forklifts still cannot get inside, and cargo conveniently already loaded on pallets must be unloaded by hand, piece by piece.

Certainly loading docks should be designed with better truck berths, but there is also a need for equipment to create slopes and eliminate height differences.

The CLIMBING LEVELER solves the problem of eliminating such steps.

Examples of Application

Use the button controls to raise the Climbing Leveler to establish a stable slope between platform and truck loading gate. (Max. angle: 9.5°; leading edge slide width: 500mm)

When not in use, the Climbing Leveler serves as ordinary usable space.

When necessary, the Climbing Leveler can eliminate the step between platform and ground.

(Max. angle: 7°; leading edge slide width: 1000mm)

Cases

-

-

-

-

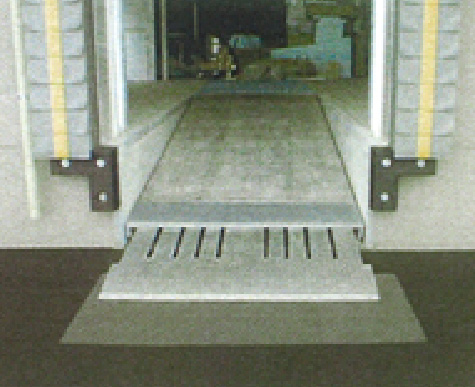

Combined use with dock shelter

Specifications and Drawings

| Load Capacity | Passing loads up to 5,000 kg |

|---|---|

| Dimensions | 1,800 mm W × 5,000 mm L |

| Lip Length | 500 mm (up) or 1,000 mm (down) |

| Operating Range | Recommended angle of 9.5° up or 7.0° down |

| Allowable Cant | L-R 50-100 mm |

| Operation | 6-button control panel |

| Safety Mechanisms | (1) Anti-descent lock (2) Anti-twist lip (4 angles) (3) Built-in maintenance stock |

| Power Source | 3-phase motor, 200V AC, 2.2kW, 4P |

| Color Main | unit: JPMA No. 542; Side cart: yellow |

| Weight | Approx. 3,730kg |

* Pitless installation means no worries about water pooling.