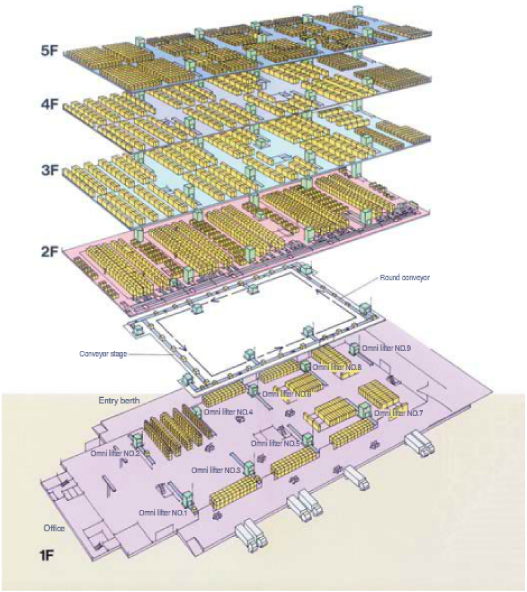

OMNI FRESH PRODUCE DISTRIBUTION SYSTEM

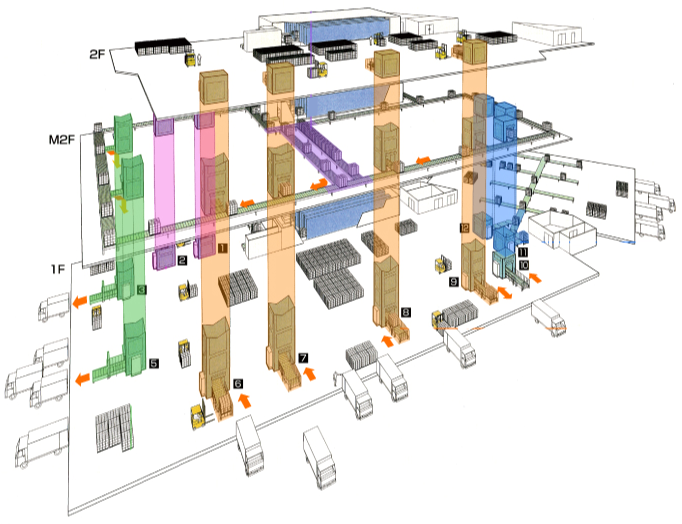

The OMNI FRESH PRODUCE DISTRIBUTION SYSTEM functionally controls 12 omni lifters and about 250 round conveyors on the mezzanine floor to drastically reduce the horizontal holding on the first floor, double the cargo handling space, and cause vehicle contact accidents. In response to the reduction, it is linked with the automated warehouse for refrigeration, making the flow of products in the market as smooth as possible.

OMNI CONVEYOR SYSTEM

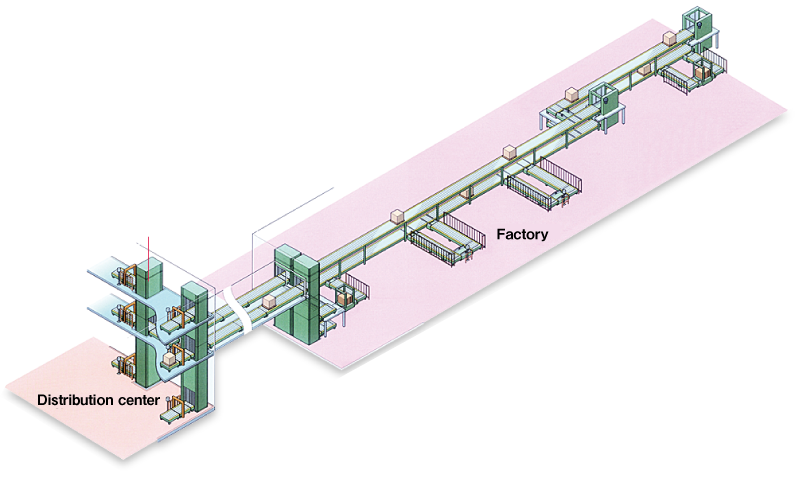

The OMNI CONVEYOR SYSTEM makes the flow of the entire delivery system smoother by combining vertical transportation by the omni lifter and horizontal transportation by the omni conveyor. Omniyoshida develops rollers for medium and heavy loads in-house and builds a system using the optimum model.We are working to improve the functions of distribution centers by adopting a more efficient conveyor system centered on omni lifters. Please use the "OMNI CONVEYOR SYSTEM".

OMNI SORTER SYSTEM

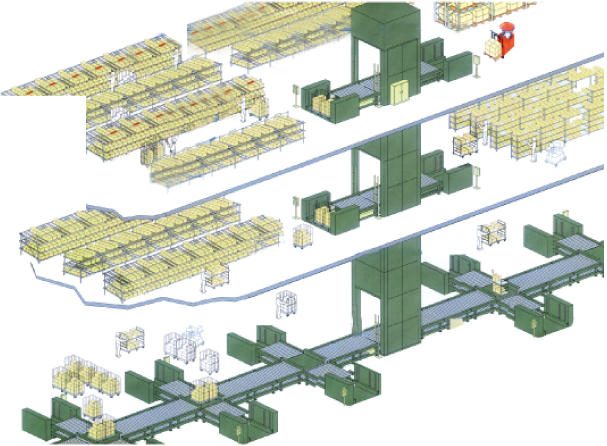

The OMNI SORTER SYSTEM is an efficient system that picks and loads assorted products on the 2nd and 3rd floors of the distribution center, and sorts the products by destination at the shipping site on the 1st floor with the products loaded.The idea of using a dedicated pallet to smoothly flow from the omni lifter to the sorting system and moving the entire trolley on the conveyor is the result of many years of experience and achievements. Please use the "OMNI SORTER SYSTEM".

OMNI AUTOMOTIVE PARTS DISTRIBUTION SYSTEM

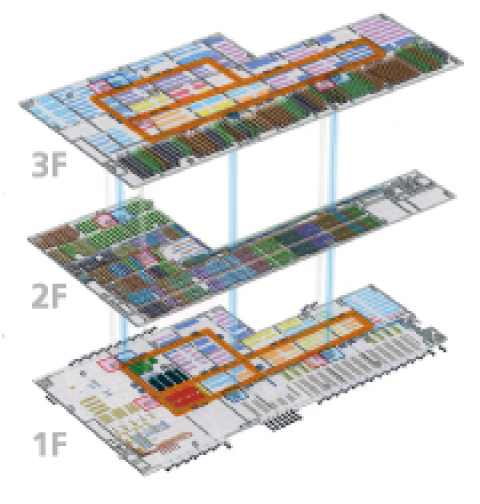

The OMNI AUTOMOTIVE PARTS DISTRIBUTION SYSTEM combines an omni lifter and an automated guided vehicle (AGV) to reduce manned forklifts and keep the operations of a three-story distribution center functioning smoothly.

OMNI HOUSEHOLD ELECTRONICS DISTRIBUTION SYSTEM

The OMNI HOUSEHOLD ELECTRONICS DISTRIBUTION SYSTEM utilizes a large number of omni lifters and combines them well with the conveyor system in order to operate the multi-story distribution center efficiently, and smoothly handles the goods received and shipped.