Summary and Features

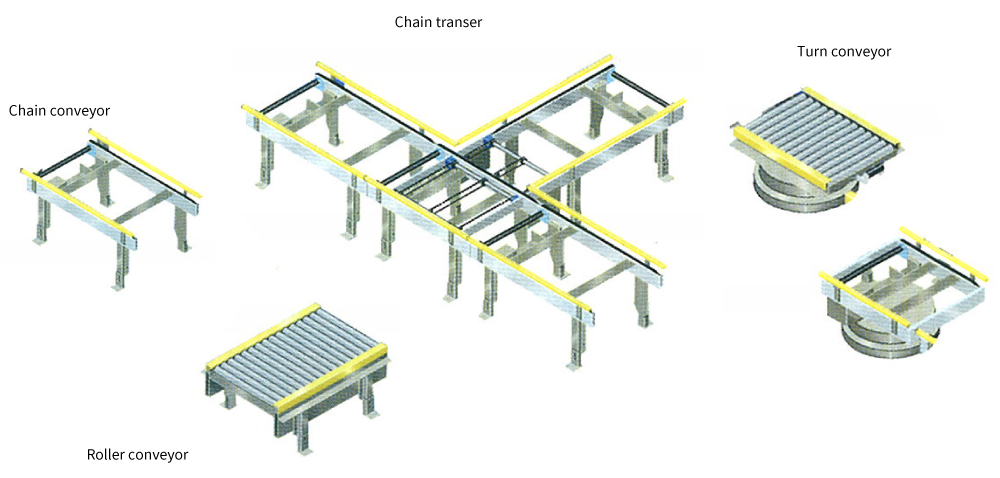

It is a pallet exchanger that can be connected to the line by mounting a roller conveyor and penetrating it.

Allows linkup with other equipment

Linkability with (or as part of) an existing line means pallets needing to be exchanged can be queued.

Linking the Palle-Thru with vertical conveyors or automated warehouse systems eliminates the need to take cargos off the line to another place just to exchange pallets.

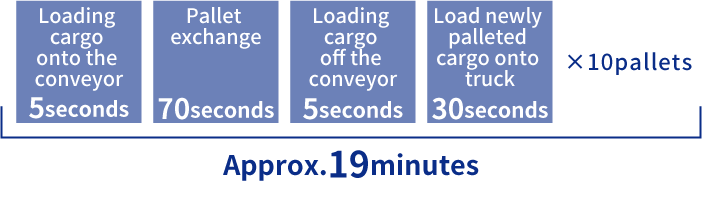

Processing Capacities

Automated exchanging takes advantage of mechanical processing for excellent speed.

Just 19 minutes to process the load for one 10-ton truck

Let’s solve the pallet exchange problem!

Recently there have been movements in certain industries, particularly foodstuffs and pharmaceuticals, to prevent pallets used in factories from being sent outside. This means that goods produced in those factories must be shifted from their factory pallets onto shipping pallets. By necessity, much of this shifting has been done manually by factory workers.

In other cases, goods arriving at warehouses and distribution centers must often be shifted from factory shipping pallets onto user pallets.

PALLE-THRU solves these pallet replacement challenges.

Control Functions

-

Control panel -

Operator touch panel -

Remote control switch

(optional)

Reference Diagrams

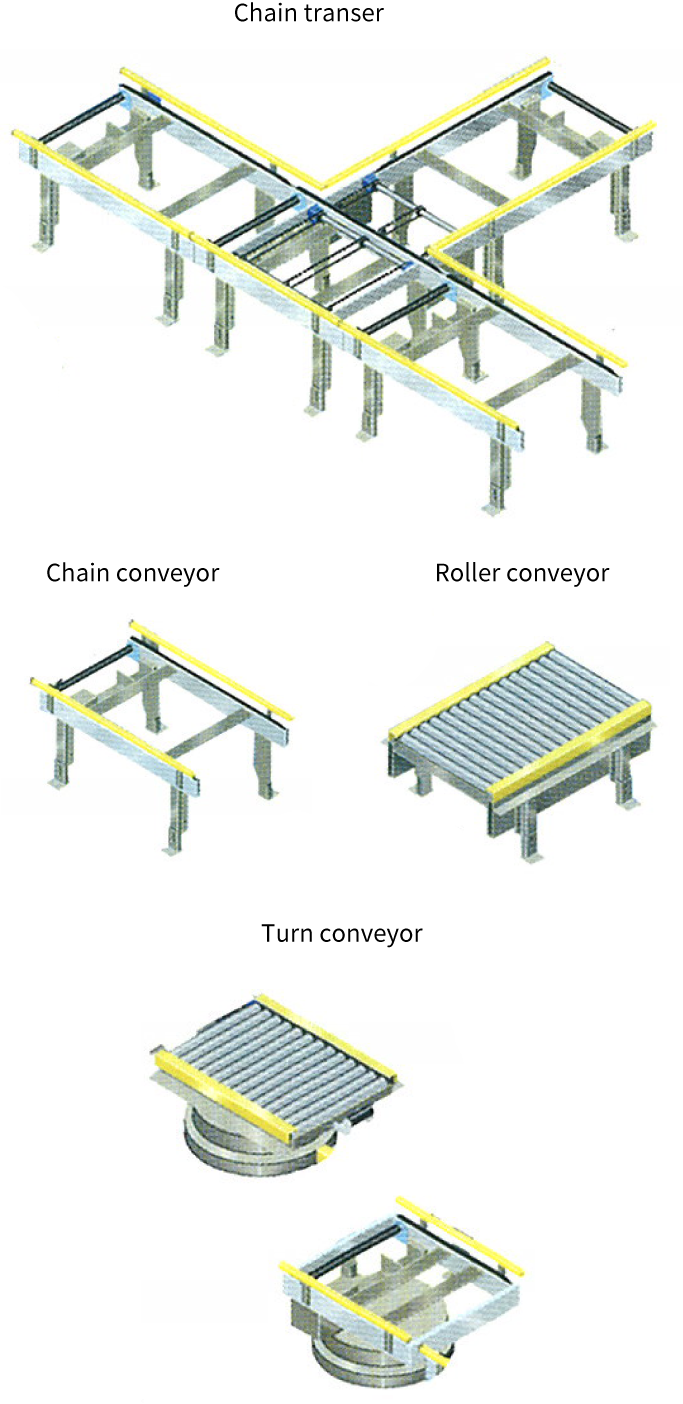

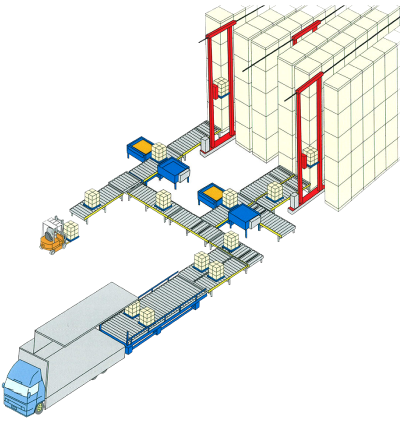

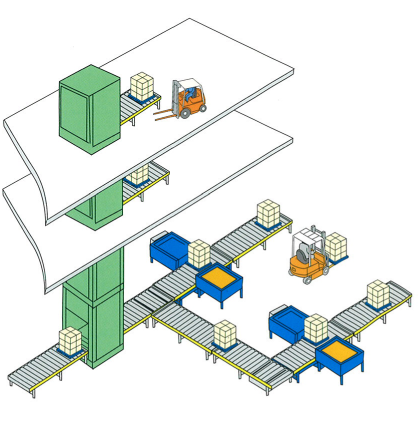

Connecting Equipment

-

Connected to an automotive parts warehouse -

Example of conveyor connections

Cases

Specifications and Drawings

| Exchanged item (plastic pallet) dimensions | 1,100W×1,100L×150H |

|---|---|

| Exchanged item (exchange pallet) dimensions | 1,100W×1,100L×150H 1,200W×1,000L×150H |

| Cargo dimensions | 1,100W×1,100L |

| Max. cargo weight | MAX 1,000kg/pallet |

| Exchange capacity | 70sec/pallet (not including time to load onto conveyor) |

| Cargo handling used | Forklift |

| Equipment and loading orientation | Front-loading |

* Please inquire regarding cargos differently sized or shaped than shown above.

* Please inquire for more details about dimensions.